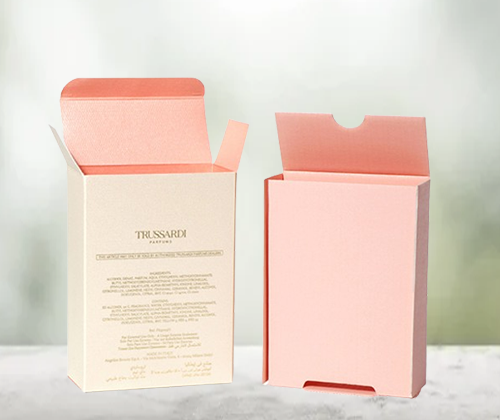

Custom Drawer Gift Box Manufacturing & Printing

Drawer boxes, often used for packaging luxury items, jewelry, cosmetics, electronics, and gifts, are popular due to their sturdy structure and elegant design. It usually consists of a sturdy hardwood or cardboard box with a sliding drawer system that makes it easy to retrieve the gift contents inside. Usually, the box's interior has slots or compartments to securely hold each product in place and stop it from bouncing around or breaking while being stored or transported. Because they offer an elegant and organized manner for showing multiple promotional items in a single package, these boxes are widely used for giving or retailing